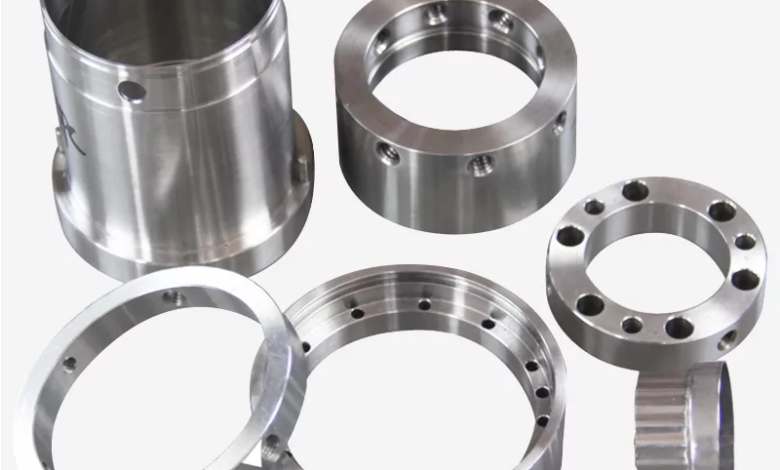

Types of Mechanical Seal

There are several different kinds of seals, each with a distinct benefit:

External Seals: Outside of the pump stuffing box, there is a seal. Seals are fitted outside when filling boxes are shallow, and it is not feasible to install one within. Additionally, installation and upkeep are simple. Outside seals are appropriate for low temperature, low speed, and low-pressure applications because of the heat dissipation that occurs below the seal faces (fluid pressure is applied outside to the seal face rather than internally in these seals).

Interior Seals: An internal seal is one that is installed within the stuffing box of the pump. Installing and maintaining inside seals might be more challenging. The ability to regulate the atmosphere within the stuffing box is the key benefit, however.

Centered Seal: There are unbalanced and balanced variants of every seal. When the fluid force needed to shut the seal faces (owing to the rotating seal face’s exposure to the pumping fluid in the stuffing box) exceeds the force applied on the spinning seal face at the point of contact, the seal is out of balance (pressure gradient between rotating and stationary seal faces). It has a seal closing power that is more than the actual pressure that has to be sealed, to put it simply. In a balanced seal, less heat is produced and the seal life is increased since the seal face is submitted to low force. The coat of a balanced seal is taller than an unbalanced seal because balancing calls for a stepped shaft sleeve.

Conclusion

Contact a reputable mechanical seal manufacturer like Junty if you’re considering investing in mechanical seals. Junty can provide you with all the knowledgeable advice and services you might need about mechanical seals. More gratifying products and effectively delivered counsel will be provided to you.