The Benefits And Advantages Of The Latest PEEK 3D Printing Technology

Did you know that PEEK 3D printing has some benefits and advantages over other materials? While this new manufacturing process is still in its infancy, it has already led to the creation of a variety of new products. Take a look at these benefits and advantages of PEEK 3D printing!

Applications of PEEK 3D printing

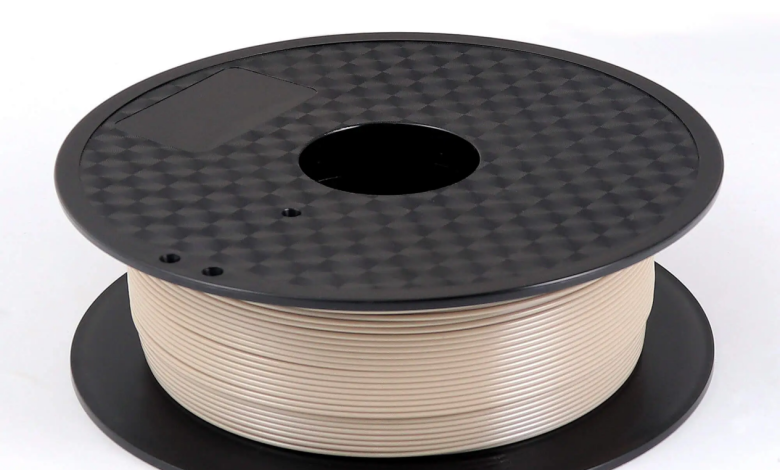

PEEK is a thermoplastic that has been specifically designed for 3D printing. The material is non-toxic, environmentally friendly, and has high thermal stability. This means that PEEK can be used in applications where other materials would not be safe or appropriate.

One of the most popular uses of PEEK 3D printing technology is in medical products. The material is often used to create prosthetic limbs and other body parts. PEEK allows for precise 3D printing of complex shapes, which makes it an ideal choice for creating custom medical devices.

PEEK also finds use in manufacturing. The material is often used in production lines where small parts are needed quickly, such as those found in electronics and car manufacturing. Due to its flexibility and low weight, PEEK is a great option for these applications where cost and speed are important factors.

Benefits of Using PEEK

PEEK is a thermoplastic polymer with excellent heat resistance, a low compression set, and good chemical resistance. It is used in a wide range of applications including engineering plastics, medical devices, and food packaging. The benefits of using PEEK include its high strength-to-weight ratio, which makes it ideal for use in products that have to endure high-stress conditions, such as aircraft components or motors.

Another advantage of PEEK is its low expansion coefficient. This means that PEEK does not change its size when heated or cooled, which is ideal for products that need to be able to withstand extreme temperatures. Additionally, PEEK has a low moisture absorption rate and good resistance to chemicals and oils. This makes it an ideal material for manufacturing medical devices, automotive components, and food packaging.

If you have any question after reading this article, you can contact Junsun Medical!