Automotive Metal Stamping Parts From Hashimoto Precision

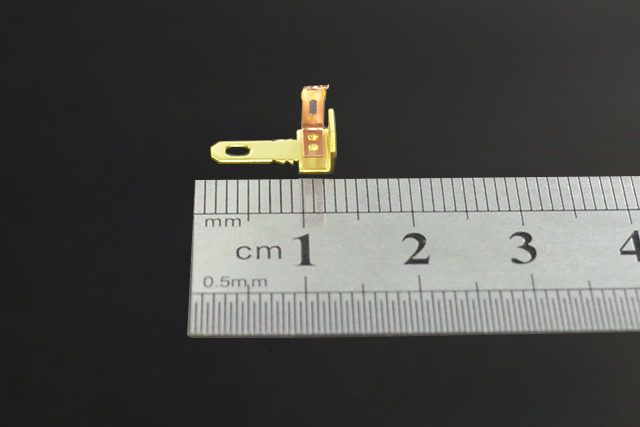

Automotive metal stamping is essential, like the charging pile terminals on electric vehicles. Recently, Hashimoto Precision has developed new technology to produce these metal stamping plates with a thickness of 0.02-2.0mm that meet the needs of electric vehicle manufacturers.

Introduction to Hashimoto Precision

Hashimoto Precision is committed to metal stamping for the automotive industry to provide high-precision and small automotive metal stamping parts.

Nowadays, Hashimoto Precision has cooperated with new energy vehicle enterprises to produce more precise automotive metal stamping parts with a thickness of 0.02 ~ 2.0mm, such as charging pile terminals, bayonet hardware, automotive terminals, automobile camera gaskets, and so on.

Automotive Metal Stamping Parts

Hashimoto Precision is the company to trust if you’re looking for high-quality automotive metal stamping parts. We have over 20 years of experience in the industry, and our parts are used by some of the top automakers in the world. So when it comes to precision and reliability, we’re second to none.

Process and Technology

The automotive industry is one of the most important industries in the world. It is responsible for the production of vehicles that are used for transportation. The manufacturing process of these vehicles requires various parts and components. One of the most important components in the manufacturing process is the metal stamping part.

Hashimoto Precision is a leading manufacturer of metal stamping parts. The company has been in business for over 20 years and has a wealth of experience in the industry.

Quality Control

Quality control is of the utmost importance when it comes to automotive metal stamping parts. Hashimoto Precision takes great care to ensure that all its parts meet the highest standards.

Hashimoto Precision has a rigorous quality control process to ensure that its parts meet these high standards. This process begins with the incoming raw materials being inspected for any defects. Once the raw materials have been approved, the parts are stamped out.

After the parts have been stamped out, they undergo another inspection to check for any defects. Once the parts have passed inspection, they are shipped to the customer.

Conclusion

At Hashimoto Precision, we understand that automotive metal stamping is a critical process in manufacturing car parts. We are committed to providing our customers with the highest quality stamped parts to their precise specifications. Our team of experts is always available to help you choose the right stamping process for your project, and we guarantee your satisfaction with our work.